Have you ever taken a look at the manufacturing sectors, the healthcare sector, or the IT sector and wondered what the process could be? Are there any rules that they have to stick by, or is there any kind of quality check that they need to focus on? So let me introduce what is Six Sigma to you; it is a data-driven tool that most organizations follow and abide by, focusing on the important aspect of Quality. It focuses on improving processes of any business by reducing errors and enhancing the overall quality. Hence, this quality-related training has taken a huge leap, and it has become a recognized standard for operational excellence.

Over a period of time, efficiency and customer satisfaction have become of utmost importance, and they can effortlessly make or break the success of any business. Six Sigma is a Quality Assessment Tool that provides organizations with the tools to streamline operations, cut costs, and deliver consistent results.

This blog gives an understanding of what is Six Sigma. how it works, and why it’s an essential skill for businesses and professionals who strive for excellence.

Let’s Understand What is Six Sigma?

Approximately a decade ago, I also had the opportunity to undergo the basic course on what is Six Sigma. This session introduced different concepts and examples, which were so relatable. One such example that was quoted and stayed with me was the services offered by the Dabbawallas in Bombay, the well-known Mumbai. They deliver hundreds of lunch boxes on a daily basis with utmost accuracy, and that shows and reflects the principles of SS, and in a gist – Quality without errors.

This concept was originally developed in the 1980s by Motorola. It can be termed as a methodology, a quality control tool that basically uses data analysis and techniques based on statistics to enhance processes. It is a quality management tool, where the term sigma represents standard deviation, and it aims to reduce errors. In the process of Six Sigma, it achieves, fewer than 3.4 defects per million opportunities, simply put together, just near perfection.

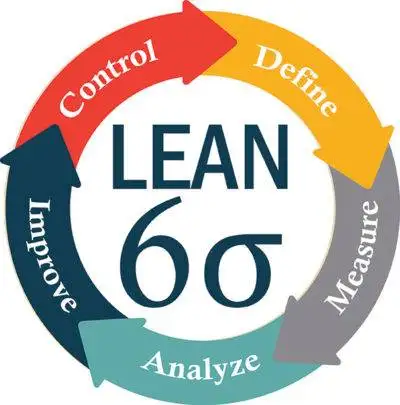

Through this training, professionals learn what is Six Sigma and a structured technique of problem solving using two main approaches:

- DMAIC is commonly used for improving existing processes

Define – set the objectives or the goals

Measure – to measure the frequencies, duration, or defect rates

Analyze – root cause analysis

Improve – to implement and improvise certain structures

Control – by tracking the defects and setting up processes to control the errors.

- DMADV is used for creating new processes.

After the process of defining, measuring, and analyzing the problem areas, designing a proper plan to work out and ensure zero defects, the verification part comes into the picture.

Why Organizations Choose Six Sigma Training?

Organizations these days face enormous challenges like global competition, customer expectations, and the expectations and pressure of being and wanting nothing but the best. What is Six Sigma and how does this training help organizations in meeting these expectations by:

- Reducing waste and defects

- Lowering operational costs

- Improving productivity and cycle times

- Enhancing customer trust and satisfaction

- Building a culture of continuous improvement

But perhaps the biggest strength of this lies in its adaptability. Let’s see how it is applied in IT, healthcare, manufacturing, and even everyday operations like food delivery.

Comparing Six Sigma Training Across Industries

| Industry | Key Focus Areas | Common Applications | Benefits of Six Sigma Training |

| IT Sector | Process reliability, error reduction, service efficiency | Reducing software bugs Improving IT support resolution time Enhancing cybersecurity accuracy | Fewer system failures Higher client satisfaction Better project delivery |

| Healthcare | Patient safety, operational efficiency, and billing accuracy | Minimizing medication errors Streamlining patient flow Reducing billing rejections | Safer patient care Reduced waiting times Stronger trust and compliance |

| Manufacturing | Product quality, process optimization, supply chain | Quality control in production Reducing defects in parts Improving supplier reliability | Cost savings Faster production cycles Increased product reliability |

What is Six Sigma from The Mumbai Dabbawallas Version Without Formal Training

To reiterate the fascinating example of the Dabbawallas, where Six Sigma quality speaks for itself without undergoing a formal training, their system talks about the principles of consistency, standardization, and error-proofing. The community has over 5000 workers who deliver 200,000 lunchboxes daily with extraordinary accuracy.

Despite minimal technology and limited resources, their error rate is so low that they are often cited as an example of Six Sigma-level efficiency.

Key Lessons from the Dabbawallas:

So what is it that the Dabbawallas have to teach us about what is Six Sigma from their point of view?

- Clear System Design – A simple coding system directs each lunchbox’s route.

- Defined Roles – Each person knows whether they are collecting, sorting, or delivering.

- Standardization – The process has been perfected over decades.

- Commitment – Accountability that drives performance.

What is Six Sigma Certification

Take Your SS Training to the Next Level

For professionals who want to pursue a career in Quality management, Six Sigma certification after undergoing proper training adds a feather to their cap. Certifications are offered at different levels, and it is represented by belts. Let’s take a look at the courses offered under different belts:

- White Belt – This course gives you an introduction to understanding the concepts of what is Six Sigma.

- Yellow Belt – the yellow belt phase supports you with basic project knowledge.

- Green Belt – While the green belt is the Intermediate level, it boosts an individual and makes them capable of leading smaller projects.

- Black Belt – This particular section pushes an individual to the Advanced level, which makes one confident in leading major processes and showing improvement in projects.

- Master Black Belt – This course makes one achieve an expert level by mentoring the individuals pursuing Black Belts and also leading from the organizational end.

Understanding Lean Six Sigma

Let me introduce you to a technology called Lean Six Sigma, apart from the belts. So, what is Lean Six Sigma?

Lean Six Sigma Training is a methodology that focuses on eliminating waste and improving the flow of the process, while it focuses primarily on reducing waste and defects. Over a period of time, businesses have realized that combining both gives better results.

Professionals also choose the Lean Six Sigma certification for various enhancing opportunities. It also has the belt system process and is highly valued across different industries.

Benefits of Six Sigma

Whatever the industry, SS training delivers measurable benefits:

- Financial reduction – Helps lower costs by reducing waste, rework, and inefficiency.

- Customer Satisfaction – More consistent quality leads to stronger trust with immense satisfaction.

- Employee Growth –This kind of training builds analytical skills and teamwork.

Challenges in Implementing Six Sigma

Along with the benefits, we cannot help but speak about the challenges that are faced while implementing S S training. A few to mention:

- It requires support from executives for long-term success.

- One has to be trained in Green Belt, Black Belt, or Master Black Belt to lead projects.

- May lead to overemphasis on metrics if not balanced with creativity.

Thus, this is the reason that structured Six Sigma training programs are essential. They prepare professionals to handle data-driven projects while fostering a mindset of continuous improvement.

Henry Harvin for Six Sigma Training

If you still have a question about what is Six Sigma, then choose a course to upskill yourself in this field. Consider going ahead with Henry Harvin. They offer online courses at an affordable price The course covers loads of informative skills, and the institute also assists you with certifications, placements, and more. The institute’s certifications are legitimate and have global values. Henry Harvin has set their foot firmly in the field of training and certification for a good time now.

In context with what is Six Sigma, they offer an online course on Lean Six Sigma, it includes a curriculum that is industry-recognized and widely appreciated.

Course Details

- Duration- 28 + hours of instructor led training

- Course Fee – AED 5400

- Mode of Delivery- online

- Trainers – the trainers have over 13+ years of experience and are subject matter experts who can guide and share their knowledge with utmost credibility.

- Skills You will Learn – Statistical Tools and Techniques, Leadership Techniques, Process Mapping and Analysis, Process Improvement Abilities, Performance Measurement Abilities, Quality Improvement, and so on

- Tools You will learn – Sig Sigma Tool, In-depth knowledge of DMAIC, Application of Lean Six Sigma principles to, etc.

- Other benefits- certifications and placement opportunities.

Not to forget to mention their timely support and placement assistance during and after the course. They also provide internship and mentorship opportunities post successful completion of the course.

So, what are you waiting for????

Conclusion

If you are a beginner who is looking to pursue a career in the field of quality, then Six Sigma can be a game-changer. This quality management tool is a mindset that places quality and customer satisfaction at the center of business operations, and it’s not just a methodology. Choose Six Sigma, choose success, choose career growth.

What else? Just dive into a new venture…

Recommended Reads

- The Future of Six Sigma: Trends and Innovations to Watch in 2025

- How to Choose the Best Six Sigma Training Program?

- The Role of Six Sigma in Quality Management: Ensuring Excellence

- Enhance Your Career with Lean Six Sigma Black Belt Training

- Unlocking the Power of Lean Six Sigma: A Comprehensive Guide

FAQ’s

Ans: Speaking from a very basic concept, Six Sigma is a tool that helps reduce errors in processes, aiming for near-perfection in quality management.

Ans: The dabbawallas from Mumbai deliver over 200,000 lunchboxes every day with near-zero errors. Their way of working demonstrates Six Sigma-level accuracy without any formal training.

Ans: Six Sigma certification aims mainly at emphasizing reducing variation and improving quality. On the other hand Lean Six Sigma certification trains professionals to identify and remove waste.

Ans: Yes, Six Sigma is highly relevant across all industries and organizations to improve quality, cut costs, and meet rising customer expectations.

Ans: Absolutely! Yellow and Green Belt training is for beginners. It helps build foundational skills before advancing to certifications.