With the pace at which things are changing in modern-day business, organizations on a global scale work tirelessly to ascertain the best ways of improving efficiency, reducing errors, and satisfying customers. Six Sigma is one methodology that has stood the test of time and remains one of the most trusted methods for improving processes and managing quality. The growing competitiveness and rapid technological advancements have made it relevant not just for defect elimination but, rather, for relevance in a fast-changing world.

As the industries digitize more and more and increasingly become sustainable, Six Sigma Programme is not just limited to being a quality management tool. It has moved on into a strategic framework for future-ready companies.Whether it is about reducing defects in manufacturing, improving patient care in healthcare, or increasing efficiency in IT and finance, Six Sigma moves forward and stretches its arms into new sectors. In 2025, its evolution is affected, besides technology, also by new market needs, making this a critical competency for professionals seeking the edge to remain competitive.

What is Six Sigma?

Six Sigma is an approach that is data-oriented for improving one’s process literally by keeping costs down in terms of defects, bringing structured frameworks like DMAIC (Define, Measure, Analyze, Improve, Control) into play in upgrading one’s quality. it equips one with numerous tools that help an employee identify inefficiencies, reduce errors, and improve productivity across various industries.

Those wonderful Six Sigma Applications across areas like manufacturing, healthcare, IT, finance, and logistics actually talk about changing the careers of people entering managerial and leadership positions.

Key Six Sigma Trends in 2025

As organizations shift toward digital-first operations, this methodologies are also undergoing transformation. Here are the biggest Six Sigma trends to watch this year:

1. Integration of Machine Learning And AI

Six Sigma is revolutionized by AI-enabled analytics by accelerating and bettering root-cause analysis. Predictive algorithms help in preventing defects prior to their occurrence.

2. Transformation Towards Digitalization

Organizations have imparted Six Sigma in conjunction with digital transformation, such that both process improvement and adoption of technology are integrated.

3. Green Six Sigma

The Six Sigma concept integrates sustainability into its tailored processes.Therefore, the eradication of unnecessary processes, the optimal use of resources, and the adoption of green practices are the three pillars of operational excellence in companies.

4. Remote & Hybrid Training Models

Consequently,Increasingly remote Six Sigma training has become popular in this age of globalization. Students now have global exposure to high-quality training programs, accessible online.

5. Cross-Industry Applications

Today Six Sigma is no longer confined to manufacturing but also adopted by other sectors such as Information Technology (IT), health care, finance, and logistics to deal with the challenges unique to their industries.

6. Human-Centric Six Sigma

In 2025 Six Sigma doesn’t just emphasize the processes; equally, people getting engaged, working together, and leading themselves in organizations will be part and parcel.

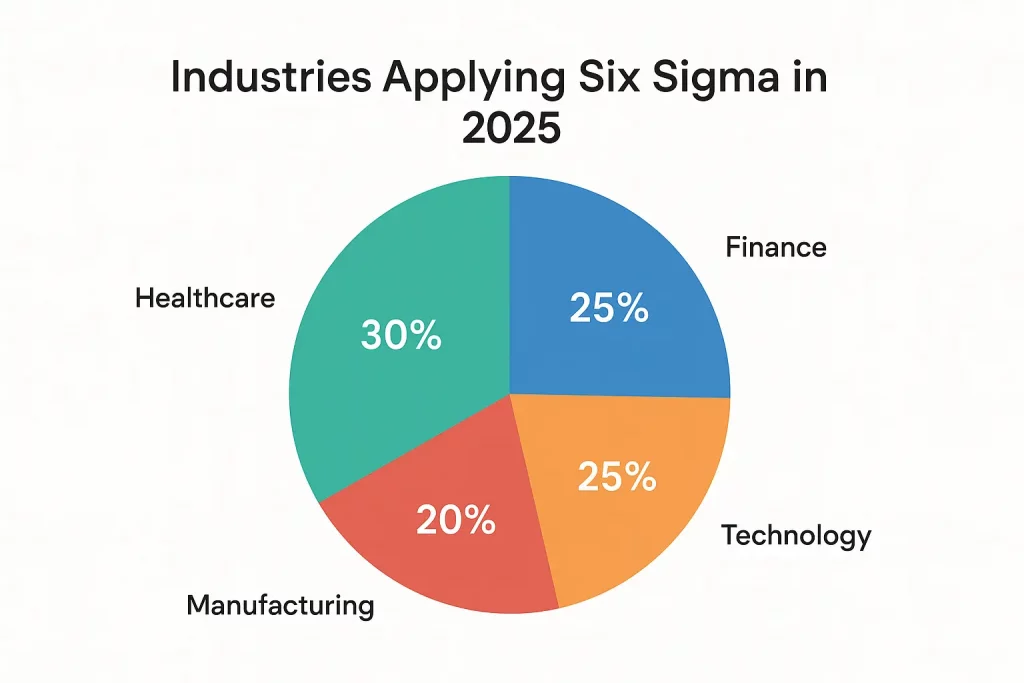

Industries Using Six Sigma in 2025

There are several industries where the Six Sigma methodology could be applied now.

1. Manufacturing- Minimizing the defects and downtime it means and ensuring a consistent product quality is what we consider as variable.

2. Healthcare – Addressing hospital and nursing home facility ambience, entertaining and engaging activities for patients, and other related factors.

3. IT & Software – Reducing bugs, bettering delivery timelines, ensuring better results for applications.

4. Finance –Reducing risk by detecting and preventing fraud.

5. Logistics – Efficiency increases in the supply chain, bottlenecks are minimized, and delivery thereby occurs if some time was wasted.

The Future of Six Sigma Innovation

Consequently,The Future of Six Sigma Innovation As organizations keep pace with a rapidly changing global economy, This methodology has changed from being solely about defect reduction.it is about continuous innovation, adaptability, and long-term impact. Look into 2025 and beyond; here is how this quality improvement approach is developing.

•AI and Machine Learning Integration

Predictive analytics shall allow Six Sigma professionals to foresee before things happen. Consequently,this innovation shall change process improvement practices from reactive problem-solving to proactive process optimization.

• Automation-Driven Management

Moreover,By ensuring robotic process automation and digital workflows, These Projects can be implemented promptly, accurately, and with less human resource dependency in performing repetitive tasks.

• Data-First Decision Making

Data management, therefore, will be a big-data-centric decision-making area in this field, supplemented with real-time dashboards that give it an evidence-based and agile perspective. Therefore,This will enable organizations to measure, analyze, and improve their processes continuously at scale.

• Sustainability & ESG Goals

Additionally,The future Six Sigma framework will focus on minimizing carbon footprint, energy wastage and environmental risk in alignment with corporate sustainability and green business practices.

•Blending Agile & Lean Startups

Long timelines were usually the order of the day for most traditional projects. Therefore,This increasingly means this methodology will be adopted by the growing 2025 with Agile and Lean practices, providing startups and SMEs with rapid and flexible approaches for quality improvement.

•Transformation of Global Talent

As a result,Professionals with this certification will drive cross-border innovation projects as companies start to accept standardized ways of efficiency in the globalized workforce.

Six Sigma Training at Henry Harvin

If you’re thinking of advancing your career in 2025, Henry Harvin runs one of the most holistic training programs that combine the age-old practices of Six Sigma with contemporary professional applications.

Some Key Course Details

Lean Six Sigma Green Belt (Live Online Interactive Sessions)

- Duration- 28hrs of live two-way online sessions.

- Fee- INR 17500 (approx.AED 800-900) for a live classroom is a common mode.As per the self-paced learning mode, the fee goes down to INR 15750.

Lean Six Sigma Green Belt (Virtual Classroom Program)

Duration- 4 Day (32 hrs) in-person delivery.

Lean Six Sigma Black Belt (UAE)

- Classroom training- 48 hrs,

- Online Training- 28 hrs.

- Program Fee: INR 25,000 (approximately AED 1,200–1,300)

Green Belt + Black Belt Combo

Duration- 64-hr comprehensive training.

What Does the Training Include?

- Masterclasses, E-learning LMS, and 1-year Gold Membership of the Quality Management Academy.

- Hands-on with DMAIC Projects to have practical applications.

- Internship and placement assistance with top MNCs like J.P. Morgan, Accenture, and Deloitte.

Henry Harvin offers such structured and feature-filled programs, ensuring you are not only certified but ready to step into the shoes of an agent of process excellence across industries.

Six Sigma: From Origins to Future Transformation

The evolution of Six Sigma through the ages indicates an inherent ability for adaptation. To begin with,In the 1980s, Motorola implemented this methodology as a method for reducing the number of manufacturing defects. Then it became a company-wide culture in General Electric under Jack Welch in the 1990s for decision-making based on data.

Moreover,in the twenty-first century, it has shifted its attention from factories toward enhancing patient safety in the health sector, risk mitigation in finance, operational efficiency in IT, and productivity in startups.

Then vs. Now

- 1980s: Defects per million opportunities- Motor Head.

- 1990s: A leadership and performance strategy in the General Electric.

- 2020s: Applied in all industries for better, safe, and fast outcomes.

History Meets New Trends

- Manual to AI & Automation: From processing data manually to powering it through machine learning and predictive analytics.

- Furthermore, Cost-Cutting to Sustainability and Digital Growth: From saving on costs to facilitating green initiatives and driving digital transformation.

- Moreover, Corporate-Only to Available to All: From an initiative for corporations and MNCs to one sought by the SMEs, professionals, and entrepreneurs through online training and certification programs.

- Static to Agile Integration: Earlier static methods now integrate with Agile and Lean to create a more flexible Six Sigma applicable to fast-paced industries.

Conclusion

Six Sigma is very optimistic about its future and the rapid improvements that will take place in the present decade of 2025. AI integration, digital harmony, sustainability, and cross-industry adopters have made this so applicable for international business growth as it matures much more over time. Professionals aspiring to be part of this opportunity wave must have a certification it is no longer an option but a necessity.

Among the top aspirant choices is Henry Harvin, well-poised with recommended trainers by industry standards and a globally accepted curriculum, and also flexible learning approaches. Therefore, you can start your journey with a Lean Six Sigma Green Belt or graduate into a Black Belt-Henry Harvin has equipped you with the skill, knowledge, and practical scoping to shine in 2025 and beyond.

Recommended Reads

- How to Choose the Best Six Sigma Training Program?

- Top 16 Six Sigma Certification in Delhi : 2025

- The Role of Six Sigma in Quality Management: Ensuring Excellence

- 5S Lean Management & Six Sigma in 2025

- Unlocking the Power of Lean Six Sigma: A Comprehensive Guide

FAQs

Ans: In the year 2025 this certification is evolving with AI, automation, and digital transformation, going even sector wise.

Ans: Definitely Six Sigma training remains highly sought after with organizations continuously looking to employ well trained professionals.

Ans: Well Six Sigma eliminates defects while Lean eliminates wastes and therefore Lean Six Sigma is a combination of both.

Ans: Simply visit Henry Harvin UAE’s website and then enroll in Green Belt, Black Belt, or combo courses.